High-Performance Silicone Defoamer for Fermentation

Enhance fermentation yield and quality with our specialized, safe, and efficient silicone defoamer.

Get a Quote & SampleProduct Core Value

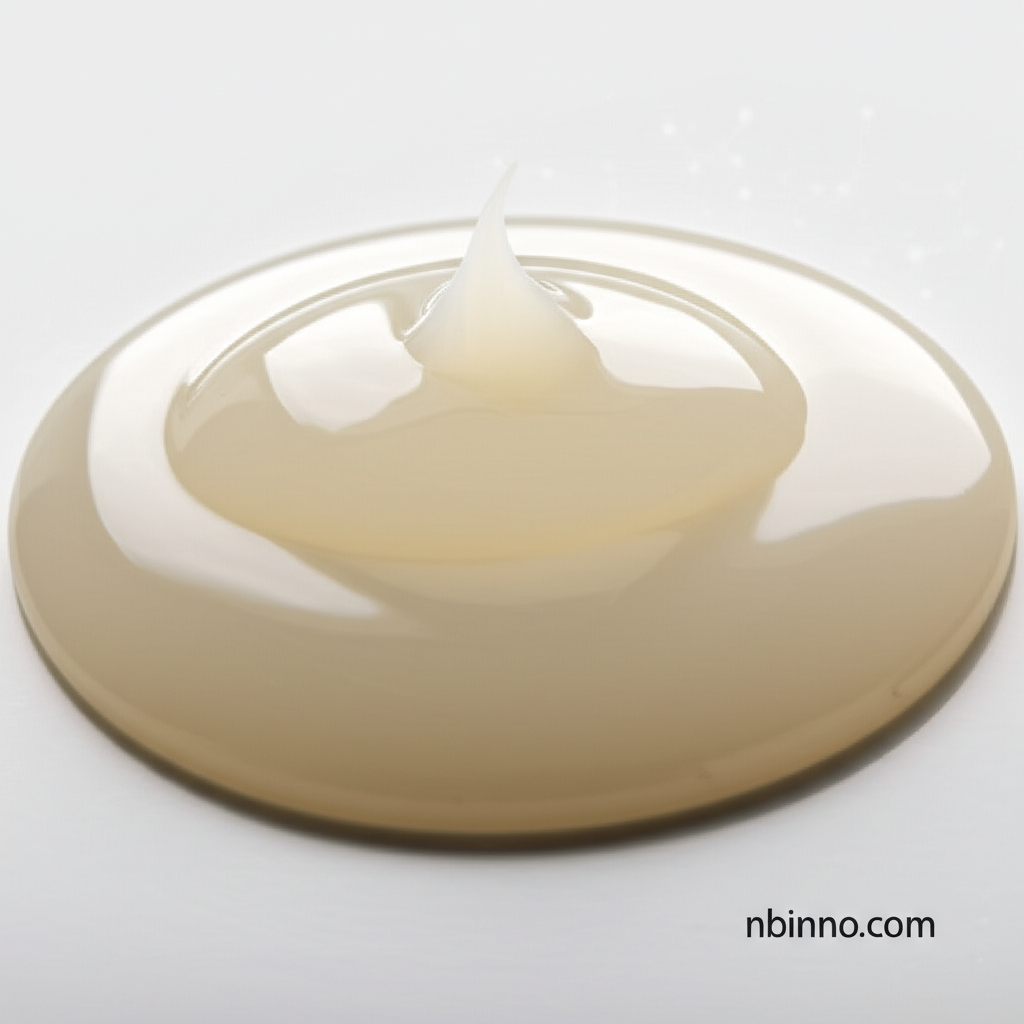

Silicone Defoamer

Our specialized silicone defoamer is engineered for the demanding needs of fermentation processes, particularly in strain culture where foam control is critical for yield and purity. Unlike less efficient alternatives, this product ensures the safety and vitality of your strains while significantly reducing operational costs.

- Experience remarkable economic benefits: this silicone defoamer can replace up to 20kg of traditional soybean oil, offering superior performance at a fraction of the cost, making it a key component for efficient microbial fermentation.

- Ensure the safety and integrity of your cultures; this non-toxic and harmless defoamer has no adverse effects on any strain, a crucial factor when selecting safe defoamer for strain culture.

- Optimize your fermentation processes with a defoamer that provides fast action and long-lasting foam inhibition, directly contributing to improved fermentation yield.

- Benefit from straightforward application and storage, with a product that remains stable for two years at room temperature, ensuring reliable performance for your chemical production needs.

Key Product Advantages

Superior Foam Control

Effectively combats severe foam in strain culture, ensuring process stability and preventing issues associated with traditional defoamers for fermentation.

Cost-Effectiveness

Offers a significant economic advantage by replacing soybean oil at a 1:20 ratio, directly lowering production costs for a key aspect of efficient microbial fermentation.

Strain Safety

Guaranteed non-toxic and harmless to sensitive strains, providing a safe defoamer for strain culture that does not compromise biological processes.

Key Applications

Vaccine Fermentation

Crucial for maintaining stable conditions in vaccine production, utilizing the effectiveness of this silicone defoamer for fermentation.

Lovastatin Production

Ensures efficientLovastatin fermentation by preventing foam-related issues, highlighting its role in improving fermentation yield.

Vitamin B12 Production

Aids in the consistent and high-quality production of Vitamin B12 through effective foam management in the fermentation process.

ARA & DHA Synthesis

Supports the complex fermentation required for ARA and DHA production with reliable antifoaming properties.